PRODUCTS FOR PROJECTS

Steel is unsurpassed for fabrication versatility. We have the expertise to maximize this by supplying a wide range of demanding fabrication, avoiding costly site works.

NOTE: The dimensions can be calculated precisely on demand and not from stock. Example Ø 1.800 mm with 19,6 mm wall can be produced against the standard 1828,8 x 20,6 mm (72” x 0,812”) leading to a saving of 58 kg/m or 6,3%.

For high grades and wall thickness, longitudinal welding is recommended, but spiral weld is recommended for long unit lengths and lower price.

SPIRAL PIPES - The latest mill for spiral pipes has several new enhancements, such as a wider strip width of 2000 mm, a Tandem Welding Plant, a Laser Weld Guidance System, new generation gearboxes, thicker hot rolled coils with a capacity of 25 mm, and the ability to handle higher grades of X70/X80 and longer unit lengths of up to 60 m without a circular weld.

It is possible to produce SPIRAL PIPES using strips of the same coil width. The displayed jumbo spiral pile has a diameter of 3150 mm and a wall thickness of 25 mm, with a length of 29 m, and weighs 54 t. Additionally, it is made from grade X 60 materials.

A 35m long Spiral Saw Monopile with Ø 1700mm and 1900mm diameter, manufactured from 32mm thick plate, was delivered to Afrikahaven in Amsterdam.

LONGITUDINALLY WELDED PILE are common in DOLPHINS/MONOPILES manufacture. They are produced from thick plates with high yield strength. The cold rolled plates are welded to form cans. Different wall and grade cans are then spliced to the required length and used as mooring or breasting dolphins with the possibility to supply the top part coated and with steel construction for fenders and bollards.

A circular welding saw machine is used to splice two cans with prepared ends for a dolphin in Mohammedia, Morocco.

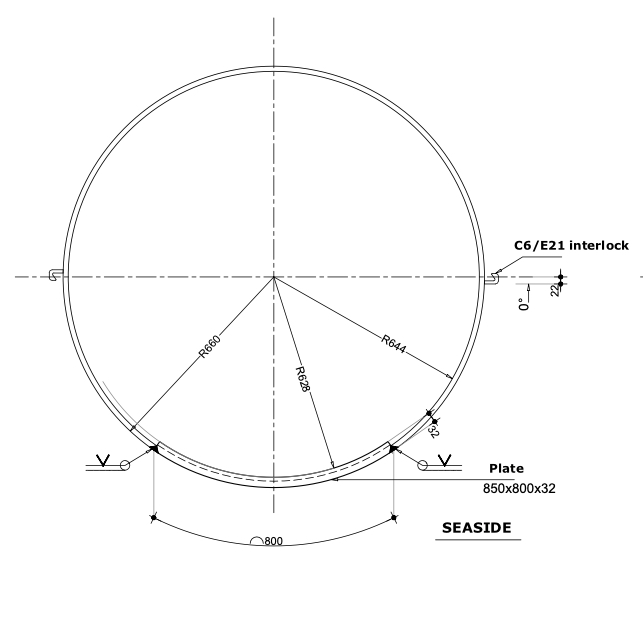

Skilled personnel craft our closed-end reinforced driving shoes, and certified welders are used. See the example drawing for Ø 1000mm.

It might be more cost-effective to weld a reinforcing plate at the maximum bending moment of a King Pile instead of increasing the wall thickness along the entire length of the pile.

SHEAR KEYS are welded flats inside piles at specified heights, inspected by dye penetrant or magnetic particle

A Piling Platform is built as a template to control the center-to-center distance of the king piles and infill sheet piles in a combi-wall. It is typically constructed with the king piles produced and shipped on deck.

PILE FLOATATION for shuttle between the anchored discharging ship and the gearless shore site.By welding on both ends plate caps with valves the delivery can be done by small motor boats to the littoral and storage by sinking to the shore.

CASING SHOE for down-the-hole hammer drilling (DTH) is mainly applied for hard to very hard rock and/or penetrating large boulders. Free issued by the manufacturer it is welded to the end of the pile.

OPENING HOLES for handling or as pictured for grouting on the bottom of pipe to pipe wall

Locking bars can be used for building stable retention walls as an alternative to sheet pile systems. They are easy to install, strong, and cost-efficient.

LOCKING-BAR submerged arc welding machine is used for pile-to-pile retaining walls with ring bit using drilling down the hole (DTH) hammers. The locking bars or interlocks/connectors are welded and supplied in male/female types.

For the combi-wall, Larssen joint sheet piles with C6/E21 interlock are welded onto the king pile. The interlock can also be supplied as E22/C9 and welded with SAW or MIG. The pile make-up drawings are included in the ITP.

When dealing with very high walls, it may be helpful to use merchant flat products made of high steel grade to increase bending moment capacity and stiffness. Instead of using interlocks and locking bars, LT profiles in Grade S 355 can be used, which are more rigid and can handle higher forces.

Anti-corrosion paint is applied in the splash zone using an airless pump after shot-blasting near white Sa 2.5/3.0-degree.

Once the surface has been prepared according to ISO 8501 and 8502, piles can be painted without the need for primer. Epoxy or glass flake epoxy paints are applied in one or two layers while monitoring the temperature and humidity. A polyurethane top coat is used to protect parts from UV rays. After the coating has cured, it undergoes holiday tests, thickness measurements, and adhesion tests to ensure its quality.

ROPE PROTECTION prevents damage to the coating during storage, handling, and transport. Stevedores protect the king piles, which are top-coated with epoxy.